In an era where sustainability and cost-efficiency are paramount, finding ways to minimize material waste and optimize production processes is a top priority for businesses. Whether you’re working on prototyping or mass production, these strategies not only reduce environmental impact but also lead to substantial cost savings. In this blog, we’ll explore some effective ways to achieve these goals and unlock the potential for economic and environmental benefits.

Implement a robust recycling and reusing system within your production facility. By recycling scrap materials and reusing parts or components whenever possible, you can cut down on waste and lower your material costs. Additionally, consider sourcing materials that have a high percentage of recycled content, reducing the environmental impact of production.

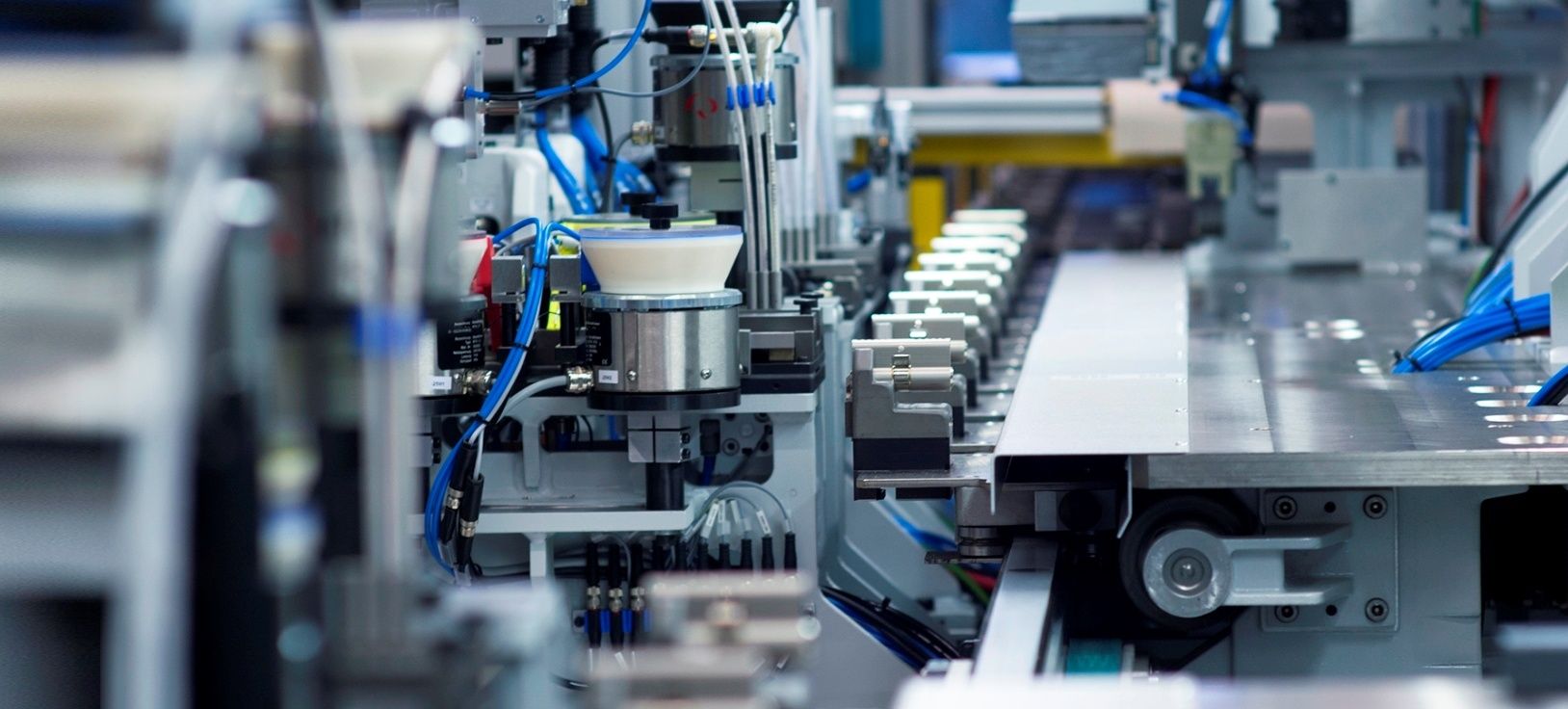

Leverage data analytics to monitor and optimize your production processes continually. Real-time data can provide insights into where waste occurs and where efficiency improvements are needed. Additionally, automation can help reduce human error and enhance efficiency, further lowering production costs.

Minimizing material waste and optimizing production processes isn’t just about reducing environmental impact; it’s also a proven way to cut costs in both prototyping and mass production. By adopting a holistic approach that encompasses design, technology, process management, and quality control, businesses can unlock the potential for significant cost savings while aligning with sustainable and eco-friendly practices. These strategies are a win-win, benefiting both the bottom line and the planet.

Copyright © 2025 For Camaero Pvt Ltd. All Rights Reserved.

Designed and Developed by Crantia Technologies